Rotary haptic module - DHM

Rotary haptic measuring systems are used to test rotary actuators in the automotive and consumer sector to record and evaluate their haptic torque curves. The rotary haptic module DHM 3 is a measuring system that has been specially developed for this purpose. It can be easily integrated in automatic and laboratory systems. The measuring range of ± 100 mNm and an integrated overload protection to prevent excessive torques allow to record the torque curves of all conventional rotary actuators. The module can be combined with the various gripper variations in the DHG3 series for adjustment to special requirements in terms of rotary actuator geometry. An integrated electric drive opens and closes the gripper. The module is designed for a minimum service life of 10 million measuring cycles.

Rotary haptic module - DHM

Rotary haptic measuring systems are used to test rotary actuators in the automotive and consumer sector to record and evaluate their haptic torque curves. The rotary haptic module DHM 3 is a measuring system that has been specially developed for this purpose. It can be easily integrated in automatic and laboratory systems. The measuring range of ± 100 mNm and an integrated overload protection to prevent excessive torques allow to record the torque curves of all conventional rotary actuators.

The module can be combined with the various gripper variations in the DHG3 series for adjustment to special requirements in terms of rotary actuator geometry. An integrated electric drive opens and closes the gripper. The module is designed for a minimum service life of 10 million measuring cycles.

Rotary haptic module DHM3

Rotary haptic measuring systems are used to test rotary actuators in the automotive and consumer sector to record and evaluate their haptic torque curves. The rotary haptic module DHM 3 is a measuring system that has been specially developed for this purpose. It can be easily integrated in automatic and laboratory systems. The measuring range of ± 100 mNm and an integrated overload protection to prevent excessive torques allow to record the torque curves of all conventional rotary actuators. The module can be combined with the various gripper variations in the DHG3 series for adjustment to special requirements in terms of rotary actuator geometry. An integrated electric drive opens and closes the gripper. The module is designed for a minimum service life of 10 million measuring cycles.

Key haptic module - THM

For recording and evaluation of key actuator force curves PANOVOTEC has developed the key haptic module THM. The module is designed to measure forces in a range of ± 40 N with an accuracy of ±50 mN (standard configuration, other range and accuracy on request) in both directions push and pull. The surrounding housing protects the system from external influences and protects the user from moving parts, so that the module can be used without a safety enclosure.

Key haptic module - THM

For recording and evaluation of key actuator force curves PANOVOTEC has developed the key haptic module THM. The module is designed to measure forces in a range of ± 40 N with an accuracy of ±50 mN (standard configuration, other range and accuracy on request) in both directions push and pull.

The surrounding housing protects the system from external influences and protects the user from moving parts, so that the module can be used without a safety enclosure.

Key haptic module THM

For recording and evaluation of key actuator force curves PANOVOTEC has developed the key haptic module THM.

The module is designed to measure forces in a range of ± 40N with an accuracy of ±50mN (standard configuration, other range and accuracy on request) in both directions push and pull.

The surrounding housing protects the system from external influences and protects the user from moving parts, so that the module can be used without a safety enclosure.

Force feedback module - FFM

Automotive interior control elements like buttons and rotary switches are increasingly being replaced by touch-sensitive surfaces. In order to provide both an intuitive interface and a save control of the vehicle, touch-sensitive controls generate haptic feedbacks like impulses or brief vibration of the surface. The Force-Feedback-Module (FFM1) of the PANOVOTEC GmbH is a measurement system that enables the user to verify force feedback in both laboratory and end of line test systems. To reproduce human haptic experience by an automated measurement the test finger has a mechanical impedance adapted to a human finger.

Force feedback module - FFM

Automotive interior control elements like buttons and rotary switches are increasingly being replaced by touch-sensitive surfaces. In order to provide both an intuitive interface and a save control of the vehicle, touch-sensitive controls generate haptic feedbacks like impulses or brief vibration of the surface.

The Force-Feedback-Module (FFM1) of the PANOVOTEC GmbH is a measurement system that enables the user to verify force feedback in both laboratory and end of line test systems. To reproduce human haptic experience by an automated measurement the test finger has a mechanical impedance adapted to a human finger.

Force feedback module FFM

Automotive interior control elements like buttons and rotary switches are increasingly being replaced by touch-sensitive surfaces. In order to provide both an intuitive interface and a save control of the vehicle, touch-sensitive controls generate haptic feedbacks like impulses or brief vibration of the surface. The Force-Feedback-Module (FFM1) of the PANOVOTEC GmbH is a measurement system that enables the user to verify force feedback in both laboratory and end of line test systems. To reproduce human haptic experience by an automated measurement the test finger has a mechanical impedance adapted to a human finger.

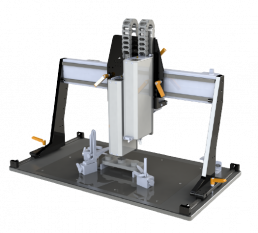

Universal device carrier (for haptic modules)

With the Universal Device Carrier for Haptic modules UDC complete PANOVOTEC the supply for components for haptic measurements in the laboratory.

The new magnetic based clamping concept allows the fixing of nearly each test sample. The magnetic stainless steel plate allows a free arrangement of the magnetic fixable clamping elements and provides an easy and straightforwardly fixing of the test sample.

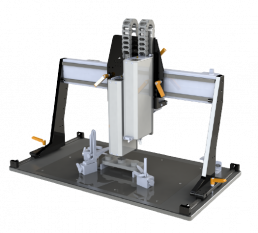

Universal device carrier (for haptic modules)

With the Universal Device Carrier for Haptic modules UDC complete PANOVOTEC the supply for components for haptic measurements in the laboratory. The new magnetic based clamping concept allows the fixing of nearly each test sample.

The magnetic stainless steel plate allows a free arrangement of the magnetic fixable clamping elements and provides an easy and straightforwardly fixing of the test sample.

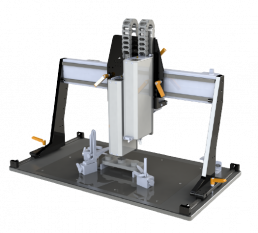

Universal device carrier (for haptic modules)

With the Universal Device Carrier for Haptic modules UDC complete PANOVOTEC the supply for components for haptic measurements in the laboratory.

The new magnetic based clamping concept allows the fixing of nearly each test sample. The magnetic stainless steel plate allows a free arrangement of the magnetic fixable clamping elements and provides an easy and straightforwardly fixing of the test sample.