SERVICES

TEST SYSTEMS & SPECIALIZED MECHANICAL ENGINEERING

SERVICES

TEST SYSTEMS & SPECIALIZED MECHANICAL ENGINEERING

The steadily accelerating demands of end customers in recent years present manufacturers and suppliers with ever new challenges. The growing demand for quality, performance, and design as well as the demand for an exceptional user experience require the highest standards in development, production and quality control.

To be able to evaluate and objectively assess the quality of products in a qualified manner and to complete the production process efficiently, inspection and testing systems are therefore also needed that provide the relevant data ever more comprehensively, precisely, reliably, but also faster.

Regardless of whether automotive, aerospace, medical, electrical, household or entertainment technology – all components, assemblies, control units and products must meet predefined tolerances throughout the entire production cycle so that they can be installed or sold directly.

With our innovative test systems, you receive test and automation solutions tailored entirely to your needs and products. Our range of services includes:

-

- The adaptation of our customizable, modular test and automation platform

- The completely new development of a inspection or testing system

- The retrofit of existing systems

The range of system solutions extends from individual test benches for sample testing, through in-line systems for seamless integration into your manufacturing process, to turnkey, fully automated end-of-line systems (EOL) for complete testing of complex assemblies and products.

We are happy to support you already in your development process with our laboratory and prototype test systems solutions.

Our flexible and customizable PANOVOTEC test and automation platform

The All-Rounder for Your Product Quality Control

Our flexible and customizable PANOVOTEC test and automation platform

The All-Rounder for Your Product Quality Control

Our flexible and customizable PANOVOTEC test and automation platform

The All-Rounder for Your Product Quality Control

Conventional inspection and test solutions are limited in their possibilities and rarely meet the high requirements of complex inspection and test procedures with, for example, several combined and coordinated measurements, inspection, and test steps.

Not so with the PANOVOTEC rotary indexing table solution for final product testing, e.g., air conditioning control units, vehicle cockpit elements, touch screens, or other operating, display and control units. Thanks to its modular design, this test system can be individually equipped with various test modules and functions according to your specifications and needs. With our proven modules, you have the possibility to perform mechanical, electrical, optical, haptic, and acoustic tests as well as complete functional tests on your DUTs.

Learn more about our proven test and measurement modules here.

Advantages of the PANOVOTEC test and automation platform

Advantages of the PANOVOTEC test and automation platform

The system is equipped with test modules of your choice and customized for you as required

By integrating all desired test and measurement stations as well as the entire system technology in one system, we achieve a high integration density with a small footprint

The high-performance rotary indexing table enables the lowest cycle times and thus a fast and reliable completion of your production process

Through continuous further development of our proven modules, we are known for our high-precision and reliable cutting-edge technology

The modular principle uses proven and continuously improved modular units – this means for you: state-of-the-art technology combined with low development costs

The inspection and test procedures could be applied to different DUTs of the same product group by specific adaptations without having to purchase a new inspection system – this ensures expandability and scalability

The high degree of automation of our solution ensures low personnel requirements. Interactive user guidance in combination with a high degree of automation almost completely eliminates operator errors.

The system automatically records and evaluates the quality of your test specimens and separately sorts out defective products with a corresponding analysis report

In addition to measuring and testing technology, other functionalities can also be integrated, such as assembly or marking units (screwdriving systems, markers, labeling devices, lasers, etc.)

By using prefabricated standard components and modules, we can offer optimized delivery times

Data networking and IT connection to your existing IT environment is possible without any problems – so nothing stands in the way of your digital transformation towards Industry 4.0

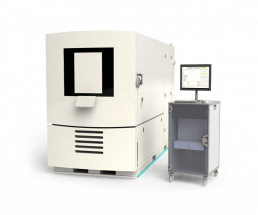

PANOVOTEC Screening systems

Your test and automation solution can also be supplied with a suitable screening system for temperature testing of your electronics, such as control units, operating or display components.

Our screening systems are characterized by quick changeover options so that they can also be used for your future product variants.

Newly developed systems according to customer requirements

Our test and automation platform does not fit your requirements and your product? No problem – the design of a completely newly developed system solution offers you the maximum customizability of the required functionalities, the system design, and the possibility to integrate the system exactly to each station of your development and production process.

Our competencies & your added value

We offer you comprehensive support, starting with the joint brainstorming, through concept development, design and manufacturing, to on-site assembly, installation, commissioning and after-sales service – all performed in-house by our Panovotec team.

By using high quality and modern technology we guarantee the best performance, the highest reliability and maximum longevity for your system.

Our designers and system developers attach great importance to future proof designs and investment security. Therefore we always develop your system with a view to possible expansion stages and future product variants.

The Panovotec team consists of experts from various fields. Regular training and further education as well as close networking in the industry are the guarantee for our know-how.

We ensure that our test systems and special machines are easy to operate. Already during the planning phase, our designers and developers think about an ergonomic workplace design as well as intuitive, simple, and clear user interface for your employees.

It goes without saying that all our systems and special machines comply with the Machinery Directive 2006/42/EC.

Measurement system analysis is done for every of our systems. For this purpose, we use our self-developed transfer standards as well as your Golden Samples and thus guarantees that our systems provide reliable data.

We are the team that helps!

Send us a non-binding message or request using our contact form.